Specifications

| Model | DZ1000 | DZ1500 | DZ2000 | DZ3000 | DZ4000 | DZ5000 |

| Total volume (L) | 1000 | 1600 | 2200 | 3200 | 4000 | 5000 |

| Volumetric coefficient | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 |

| Mixing power (kW) | 11 | 18.5 | 22 | 30 | 55 | 75 |

| Discharging power (kW) | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Weight (kg) | 2000 | 2700 | 3500 | 4600 | 5800 | 7600 |

Note: Equipment specifications are subject to change as we continuously enhance and update product performance. Please refer to the actual equipment for exact details.

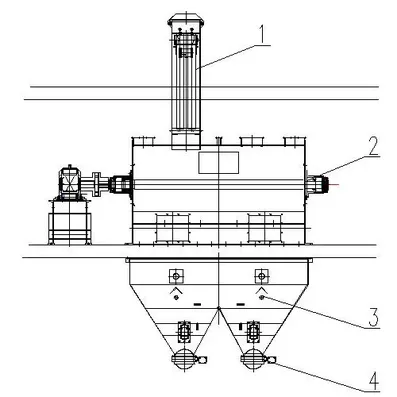

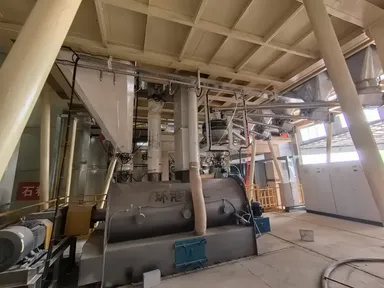

Structural Overview

- Dust Collector

- Mixing Chamber

- Mixed Material Storage Tank

- Butterfly Valve Discharge

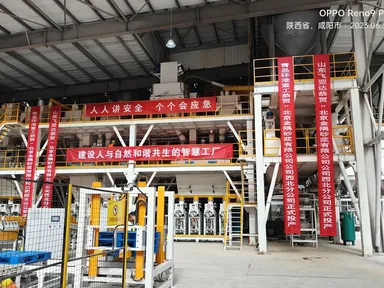

Applications

This mixer efficiently blends raw materials for building materials such as dry mortar, putty powder, tile adhesives, and gypsum products, ensuring consistent quality.

Features

- Single shaft mixers use an industrial gearbox instead of traditional chain transmissions, providing more reliable operation and reducing maintenance.

- A dual sealing structure combining mechanical and pneumatic seals prevents leakage effectively during the mixing process.

- Replaceable wear-resistant mixing paddles and wear-resistant liners guarantee prolonged usage, typically up to 200,000 tons of mortar production without replacement.

- The mixing system thoroughly mixes raw materials, ensuring uniformity and improved mixing quality.

- Large hydraulic discharge doors speed up unloading times, improve production efficiency, and minimize material residue after discharge.

- High-speed dispersing blades break up and prevent clumping in agglomerating materials, resulting in faster mixing and improved mixing precision.

- Capable of mixing materials with significant variations in density, particle size, and shape without causing segregation.

- Compared to traditional ribbon mixers, single shaft mixers provide enhanced mixing efficiency, lower energy consumption, and more consistent results.

Component Overview

-

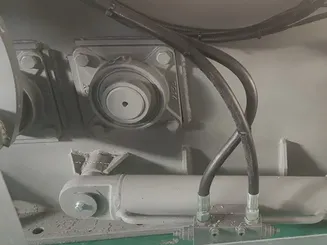

Shaft End Sealing System

A dual sealing mechanism, combining both mechanical and pneumatic seals, effectively prevents oil leakage at the shaft ends. This ensures the mixing process remains clean and contamination-free, preserving the integrity and quality of the materials.

-

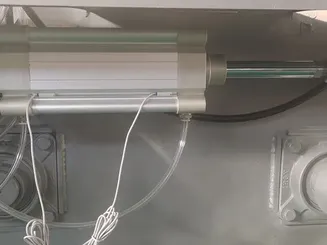

Hydraulic Discharge System

Equipped with a manual door-opening mechanism, the hydraulic discharge system allows manual operation to safely open discharge doors even during power outages, ensuring uninterrupted workflow and ease of maintenance.

-

Auxiliary Arm

The auxiliary arm assists in securely closing the discharge door, providing safer and easier operation.

-

Mixing Device

Two mixing shafts rotate in opposite directions at precisely calculated speeds, creating a zero-gravity environment through centrifugal force. This allows the materials to blend thoroughly and evenly, achieving excellent mixing efficiency.

-

Auxiliary Locking Device

This device ensures the discharge door remains securely locked, effectively preventing any material leakage during operation.

-

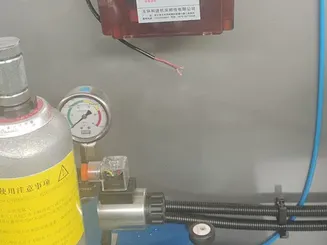

Shaft-End Oil Seal

An automatic lubrication system continuously lubricates the main unit, effectively protecting the shaft ends and ensuring smooth, reliable operation.